Peking University successfully develops super-strong carbon nanotube fibers, whi

Recently, the team led by Academician Zhang Jin from the College of Chemistry and Molecular Engineering/College of Materials Science and Engineering at Peking University, along with the Beijing Graphene Research Institute, has prepared a carbon nanotube fiber with a dynamic strength as high as 14 GPa, which far exceeds the performance of existing high-performance fibers.

Review experts have stated that this is the first time the dynamic strength of carbon nanotube fibers has broken through 10 GPa in this work, which is an unprecedented result and has significant implications for the field of fibers, especially in the realm of carbon nanotube fibers.

When subjected to high strain rates or ballistic impacts, the high-strength carbon nanotube fibers prepared in this study exhibit excellent dynamic strength and impact resistance, demonstrating strong application potential in the field of impact protection.

For example:

In the field of aerospace, high-strength carbon nanotube fibers can be used as skin materials for aircraft to prevent fragment impacts. They can also be made into space capture nets for capturing and recycling space debris.

In the field of rail transit, high-strength carbon nanotube fibers can be used for some key load-bearing and energy-absorbing components."Three Questions" about Carbon Nanotubes

Advertisement

Fibers are one of the greatest discoveries of humanity, significantly propelling the development of human civilization, and have become one of the indispensable important materials in contemporary society.

At present, fibers have been utilized in every aspect of human life, including high-precision equipment and daily necessities.

With the demand for new applications and the development of new technologies, fiber materials are gradually evolving towards ultra-performance, multifunctionality, and intelligence.

The development trend of fiber properties is mainly reflected in three aspects:Firstly, lightweight and high strength is one of the eternal pursuits of fiber materials;

Secondly, the integration of structure and function is the inevitable path for the development of fibers;

Thirdly, intelligence is an important trend in the development of fibers.

Therefore, the innovation and development of fiber materials have put forward higher requirements for the structure and performance of the basic fiber materials.

Carbon nanotubes and graphene are both low-dimensional carbon materials composed of carbon atoms sp2 hybridized hexagonal ring structures, which show excellent properties compared to traditional materials and are considered to be the ideal assembly units for the new generation of high-performance fibers.Especially as one-dimensional tubular nanocarbon materials, carbon nanotubes possess excellent properties such as lightweight, high strength, high modulus, high electrical conductivity, and high thermal conductivity.

Their theoretical strength is 100-200 GPa, the theoretical modulus is greater than 1000 GPa, the electrical conductivity is approximately 10^8 S/m, and the thermal conductivity is approximately 6600 W/(mK).

When carbon nanotubes are aligned along the axial direction, they can form carbon nanotube fibers. As a one-dimensional macroscopic material, carbon nanotube fibers are expected to effectively transfer the excellent properties of carbon nanotubes at the microscopic scale to the macroscopic fibers, thereby contributing to the creation of lightweight, high-strength, and integrated structural-functional intelligent fibers.

However, due to the challenges in the cross-scale assembly of carbon nanotubes, carbon nanotube fibers may have high porosity, low orientation, and weak inter-tube interactions, resulting in their performance still being far below the theoretical values.

Based on years of experience in the controlled preparation and characterization of carbon nanotubes, Academician Zhang Jin's team has carried out research on the controllable preparation and application technology of carbon nanotube fibers, focusing on the following three aspects:First, how can we build a bridge from the microscopic to the macroscopic fiber for carbon nanotubes?

Second, how can we achieve the cross-scale transfer of the excellent properties of carbon nanotubes from the microscopic scale to the macroscopic fiber?

Third, how can we achieve the large-scale preparation of high-performance carbon nanotube fibers?

For an ideal fiber, its structure should meet the following three requirements:

First, the molecular weight of the basic material is high, and there are few chain ends.Secondly, the molecular chains can achieve perfect orientation along the fiber axis;

Thirdly, it possesses perfect inter-chain stacking.

Only by meeting the above three conditions can the excellent properties of the basic material be effectively transmitted to the macroscopic fiber.

For carbon nanotube fibers, to fully demonstrate the excellent performance of carbon nanotubes at the microscopic scale, it is necessary to use high-quality basic materials and achieve high orientation and high-density cross-scale assembly.

Previously, the team from Tsinghua University has demonstrated that carbon nanotube bundles that meet the above conditions can achieve a mechanical strength of 80GPa, which basically meets people's expectations for the performance of carbon nanotube fibers.This also indicates that the orderly assembly of carbon nanotubes plays an important role in the performance of the assembled body.

However, the current carbon nanotube fibers still have some assembly structural issues, such as high porosity, low orientation, and weak inter-tube interactions.

To address this, the team conducted systematic optimization of the fiber's cross-scale structure, hoping to tap into the fiber's performance potential.

They drew some inspiration from the physiological phenomenon of "affecting human muscle through exercise."

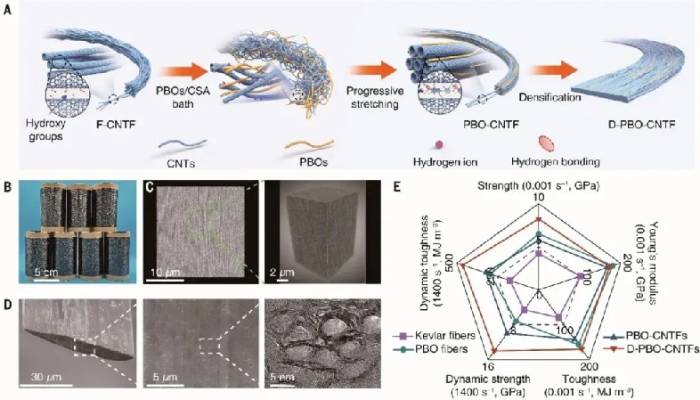

When subjected to a certain amount of strength training, the number and size of human muscle fibers will increase, and the muscle's contractile force will improve, thereby making the muscle more compact and significantly increasing muscle strength.Inspired by this phenomenon, they conducted a "mechanical training" on carbon nanotube fibers, allowing the carbon nanotubes within the fibers to rearrange, orient, and assemble.

As a result, the carbon nanotube bundles will increase in size, and the fibers will become more compact.

In addition, some fitness enthusiasts will also supplement with protein to promote muscle repair and growth.

Inspired by this, when conducting "mechanical training" on the fibers, the research team introduced a rigid rod-like polymer molecule into the fibers.

This polymer molecule acts as a "nutrient solution" for the carbon nanotube fibers, thereby enhancing the compactness and inter-tube interactions of the fibers.Then, through the process of mechanical compaction, the research team systematically optimized the structure of the fibers at the molecular scale, nanoscale, and microscale, allowing the fibers to possess excellent quasi-static mechanical properties.

By doing so, the team prepared this kind of carbon nanotube fiber, which has the characteristics of high density, high orientation, and strong inter-tube interactions.

Not stopping at "preparation," it is important to understand not only the "what" but also the "why."

Subsequently, they compared the fiber's Cunniff velocity (a traditional ballistic performance evaluation index) and found that the fiber's Cunniff velocity exceeded 1100 m/s, far higher than that of similar high-performance fibers.

In general, when testing the mechanical strength of fiber materials, people commonly use quasi-static testing conditions.During this period, the carbon nanotubes within the fiber will have enough time to undergo rearrangement and sliding, making it difficult to exhibit the excellent performance of carbon nanotubes.

Not only is this fiber structurally ordered, but also has strong inter-tube interactions. Under high-speed loading conditions, will there be different mechanical behaviors? At the same time, can the impact resistance of the fiber be directly evaluated through experiments?

They, in collaboration with researchers from the Institute of Mechanics of the Chinese Academy of Sciences, Dr. Wu Xiangqian and Dr. Lei Xudong, used the micro-scale high-speed impact tensile test method to study the mechanical behavior of the fiber under high strain rate loading.

The results show that: as the tensile speed increases, the brittle fracture mode of the fiber will change, and then exhibit a significant strain rate strengthening effect.

When the strain rate is about 1400s^-1, the dynamic strength of the fiber reaches 14GPa, far exceeding other high-performance fibers.Further, by employing an experimental method of high-speed lateral impact induced by a strong laser, they studied the dynamic response of the fiber under simulated ballistic impact loading.

The results showed that the fiber's specific energy dissipation power reached (8.7±1.0) × 10^13 mkg^-1s^-1, which is much higher than that of traditional bulletproof fibers. This indicates that the fiber has great potential for application in the field of impact protection.

Why does the fiber have such high dynamic strength?

Subsequently, the research team had in-depth discussions with Associate Professor Gao Enlai from Wuhan University to reveal the source of the excellent mechanical properties of carbon nanotube fibers.The experimental and simulation results indicate that the inter-tube interaction, orientation, and fiber compactness of carbon nanotubes are key to enhancing the mechanical properties of the fibers.

Under high-speed loading conditions, the proportion of carbon nanotube fractures within the fiber is higher. As for the fiber fracture mode, it will also shift from inter-tube slippage of carbon nanotubes to more fractures of the carbon nanotubes themselves, thereby endowing the fiber with excellent dynamic mechanical properties.

At the same time, they have collaborated with Researcher Zhang Yongyi from the Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences, and have preliminarily achieved the continuous preparation of high-strength carbon nanotube fibers and yarns.

Recently, the related paper was published in Science[1] under the title "Carbon nanotube fibers with dynamic strength up to 14 GPa."

Dr. Zhang Xinshi from Peking University, Dr. Lei Xudong from the Institute of Mechanics of the Chinese Academy of Sciences, and Ph.D. student Jia Xiangzheng from Wuhan University are the co-first authors.Peking University School of Chemical and Molecular Engineering/School of Materials Science and Engineering/Beijing Graphene Research Institute, Academician Zhang Jin, Associate Researcher Jian Muqiang from Beijing Graphene Research Institute, Researcher Wu Xiancian from the Institute of Mechanics, Chinese Academy of Sciences, Associate Professor Gao Enlai from Wuhan University, and Researcher Zhang Yongyi from Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences/University of Science and Technology of China/Jiangxi Province Institute of Nano-Tech, serve as co-corresponding authors.

In summary, this work has laid a solid foundation for a deeper understanding of the cross-scale transfer rules of the excellent properties of carbon nanotubes and the development of large-scale preparation technology for high-performance carbon nanotube fibers.

Subsequently, they will continue to explore the cross-scale transfer of the excellent properties of carbon nanotubes from the microscopic scale to the macroscopic fiber by combining multi-scale theoretical calculations and AI technology.

They will also focus on optimizing the microstructure of the fiber from the intrinsic structure of the carbon nanotubes and the assembly structure of the fiber, building a bridge from the microscopic carbon nanotubes to the macroscopic fiber.

At the same time, they will continue to develop large-scale preparation technology and equipment for high-performance carbon nanotube fibers, and work with partners to advance the work from single fiber, to fiber bundles, and then to composite material molding and processing."There is still much work to be done in these areas, and we welcome the exchange and cooperation with various advantaged teams from both domestic and international sources," said the team.

At the same time, the research group also places special emphasis on the integration of AI with research directions, and has already made preliminary explorations in AI-assisted carbon nanotube preparation and dispersion, as well as fiber preparation and structural analysis.

"The relevant papers on the integration with AI technology will also be online soon, and we will share them with everyone at that time," the researchers concluded.