Scientists develop a "lab on a fiber," capable of decoding the physical and chem

Recently, Professor Guan Baiou, Researcher Huang Yunyun, and their team from Jinan University have developed a micro-nano optical fiber "laboratory on a fiber."

It can be used to simulate the photoelectrocatalytic reactions on the surface of optical fibers and perform real-time analysis, as well as address the challenges faced when measuring key parameters of photoelectrocatalytic surfaces.

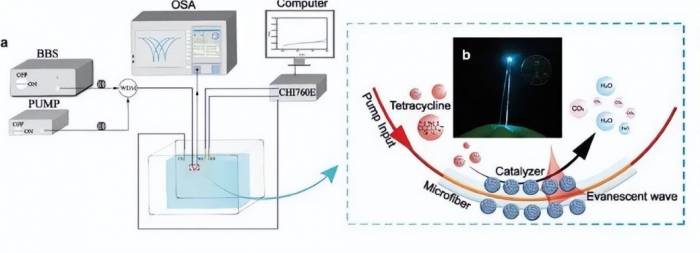

In the study, the research team assembled a layer of photoelectrocatalyst on the surface of the micro-nano optical fiber in an orderly and quantitative manner, thereby forming the micro-nano optical fiber "laboratory on a fiber."

Then, they replaced the light source that excites the catalytic reaction with a pump laser and coupled it into the optical fiber.

Subsequently, they excited the photocatalytic effect on the surface of the optical fiber through the evanescent field, achieving the simulation of the photoelectrocatalytic reaction process.Due to the rapid response capability of the transient field and its penetration depth within the sub-micrometer range, it is capable of sensing the reaction processes in the "laboratory on a fiber" on the surface.

Advertisement

At the same time, it can also monitor the concentration of reactants and thermal effects on the catalyst surface in real time, which are two key parameters.

In general, this achievement has brought a new method for monitoring the photoelectrocatalytic process and heat production, filling a significant gap in the previous monitoring technology.

It not only achieves real-time, in-situ, and sub-micrometer-level analysis for chemical and thermal events but also demonstrates significant progress in the field of photoelectrocatalytic monitoring, which is of great importance for the development of photochemical analysis technology.

In terms of application prospects, this technology can be directly used in photoelectrocatalytic reactions to monitor the changes in the concentration of reactants on the catalyst surface and the heat production process in an in-situ, real-time, and continuous manner.At the same time, it can also decode other physical and chemical events within the sub-micrometer scale range near the sensor.

Not a simple "lab on a fiber"

To understand this achievement, we have to start with solar energy.

As a clean energy source, solar energy has the advantages of being clean, safe, sustainable, and pollution-free. It can be transformed into chemical energy for use, thus providing a potential way to solve environmental pollution and energy shortage.

Photocatalytic technology is a technology that can convert solar energy into chemical energy under mild conditions without causing any secondary pollution. It is also an important way to solve environmental problems and energy challenges.Therefore, in recent years, a large number of excellent designs and syntheses of photoelectric catalysts have emerged almost every year.

In the catalytic process, the change in the concentration of reactants on the surface of the catalyst and the heat generated by catalysis are key parameters that affect the evaluation of catalytic efficiency and the interpretation of the reaction mechanism.

These two parameters dominate the macroscopic reaction of the catalyst and have an important impact on the evaluation of the internal structure-function relationship of the catalyst.

In order to deeply understand the mechanism of photoelectric catalysis and further improve catalytic performance, it is very necessary to carry out monitoring and analysis of the local concentration of reactants and temperature changes on the surface of the catalyst from the macroscopic scale to the microscopic scale.

Previously, many studies have been committed to finding new characterization methods to provide valuable catalytic parameter information.The characterization techniques include: gas chromatography-mass spectrometry, ultraviolet-visible absorption spectroscopy, and Raman spectroscopy. In addition, thermocouples, scanning thermal microscopes, and infrared thermal imagers are also used to detect the temperature of the catalyst.

However, these methods typically require large, expensive, and complex instruments, and lack the ability for in situ continuous monitoring.

On the microscale, especially at the solid-liquid interface, there is a significant challenge in continuously monitoring the reactant concentration and the surface temperature of the catalyst in situ.

The reason is not only the low resolution of the detection tools but also because the surface materials and heat will quickly diffuse into the solution.

At the same time, it has been difficult for people to capture localized surface materials and thermal signals in a fast, high-precision, and high spatial resolution manner.In addition, fluctuations in the material and temperature of the environment will inevitably interfere with the monitoring of key parameters on the catalyst surface, thus posing significant obstacles to the study of catalytic mechanisms.

To address this challenge, it is necessary to develop new sensor technologies capable of obtaining information on key parameters of the catalyst surface at the sub-micrometer scale.

Fiber optic sensors offer a highly promising approach to solving the aforementioned problem. Made from chemically inert silica glass, they have high sensitivity, instantaneous response, and electromagnetic interference resistance.

Utilizing the evanescent field at the sub-micrometer scale, fiber optic sensors can interact with substances within the sub-micrometer range on the surface.

In recent years, the emerging "lab-on-a-fiber" concept has integrated functional nanostructures onto the external surface of the optical fiber, providing many possibilities for exploring new functionalities of optical fibers.Thanks to the longer interaction length and more readily available micro/nano technology, "lab-on-a-fiber" allows people to construct multifunctional photonic components along the surface of optical fibers.

Among the existing optical fiber sensors, micro-nano optical fibers have a compact sensing structure that allows light to penetrate the entire fiber environment under the cladding mode.

Therefore, it can promote strong interactions between light and matter on a sub-microscopic scale, making it very suitable for micro-scale experiments, which can then be used to study the interactions of light physics and photochemistry.

"This is an expression that every researcher will have."For many years, the team of Guan Baiou and Huang Yunyun has been dedicated to the research of fiber optic biochemical sensors. Previously, they had developed a fiber optic sensor with the advantages of compact structure, convenient operation, and suitability for in-situ monitoring.

Thus, they conceived the idea: Is it possible to develop a fiber optic sensor integrated with a microreactor, to achieve catalytic reactions on its surface, and to use the interaction between surface light and matter to achieve real-time monitoring of key parameters of the catalytic reaction?

To this end, they carried out this project and found that in the process of forming the reaction layer on the surface of the fiber optic, in order to ensure that the fiber optic can achieve the repeatability of information and the sensor in each reaction process, the catalyst must be assembled in a single layer and in an orderly manner.

Therefore, they tried various methods of functionalizing the surface of the fiber optic, achieving quantitative and orderly assembly of the catalyst layer.

Integrating the external catalytic reaction excitation light source into the fiber optic and transmitting the excitation light of the catalytic reaction through the fiber optic is also one of the key objectives of this project.Therefore, only in this way can the device become more integrated and more miniaturized, which is also conducive to the application of the device.

For this purpose, they performed a thinning treatment on the optical fiber diameter to allow the pump light source to be evanescent in the tapered region of the optical fiber to the surface, thereby exciting the catalytic reaction of the surface catalytic layer.

Liang Jiaxuan, a doctoral student at Jinan University and co-first author of this paper, said that the optical fiber sensor required this time must have the characteristics of a compact structure and high sensitivity, which makes the device manufacturing particularly complex.

During this period, they continuously experimented with the type of optical fiber, the size of the micro-fiber, and the power of the Bragg grating laser, and finally made a micro-fiber sensor that can meet the experimental requirements.

Liang Jiaxuan said: "I still remember the disappointed expression of my master's sister every time she tried and failed, which is an expression that every scientific researcher will have. But I often comfort: if it doesn't work, change it, be confident."He took the failure of the experiment quite calmly: after all, not all experiments will proceed as planned, but experience can be accumulated from every failure.

He and his junior female fellow student had seen the campus of Jinan University at 4 a.m. to ensure the use of instruments, and they were often noted as returning late by the dormitory aunt due to experiments.

Liang Jiaxuan continued to say: "The successful submission of the paper and the smooth receipt of DOI is also our most unforgettable moment, which makes us feel that everything we have done is worthwhile."

"I remember that we were still having a group meeting at that time. After receiving an email, the mentor Huang Yunyun showed a long-lost smile and said to me and my junior female fellow student: 'The paper has been officially accepted, and there is a DOI (Digital Object Unique Identifier).'" He said.

At that moment, for the mentor Huang Yunyun, it may have been a relaxed and calm process, but for Liang Jiaxuan and his junior female fellow student, it was a milestone in their academic career, which means that they can finally graduate smoothly.Ultimately, the relevant paper was published with the title "Operando Decoding of Surface Chemical and Thermal Events in Photoelectrocatalysis via a Lab-Around-Microfiber Sensor" in Advanced Science (IF 14.3).

Huang Yunyun is the first author and co-corresponding author, Mou Caini and Liang Jiaxuan are co-first authors, and Professor Guan Bai'ou from Jinan University serves as the co-corresponding author.

As mentioned earlier, this team focuses on the research of optical fiber biochemical sensors.

Currently, in the field of biology, they are conducting clinical detection and treatment of bacteria and tumors, and have completed the detection of clinical samples, and are currently collaborating with medical experts.

In the field of chemical sensing, in addition to researching the detection of key parameters of catalysts, they are also using sensors to study electrical signals and bioelectricity production. It is believed that soon, they will also welcome new surprises.